Singapore PCBA Productions A pleasant shopping experience

PCBA Solution Board Design and Development: Technology, Process, and Applications

What is PCBA Solution Board?

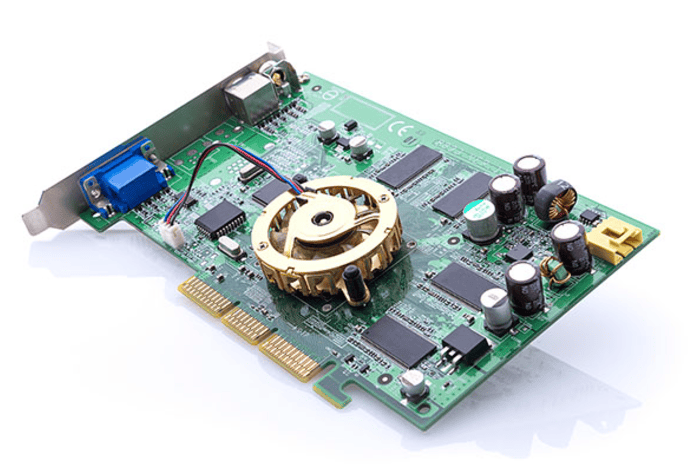

PCBA (Printed Circuit Board Assembly) solution board is an essential part of electronic products, combining circuit boards and electronic components to form a complete electrical connection system. The design and development of PCBA solution boards include the entire process from circuit board design, component selection, routing, to assembly and testing. It is a critical step in the electronic product manufacturing process and is widely used in fields such as consumer electronics, communication devices, industrial automation, and medical equipment.

Main Processes in PCBA Solution Board Design and Development

- Requirement Analysis and Product Definition

Before designing a PCBA solution board, it is crucial to conduct a requirement analysis to define the product’s functions, performance needs, and working environment. The goal of this stage is to ensure that the design plan aligns with customer requirements, providing clear direction for the subsequent design and development phases. - Circuit Design and Schematic Drawing

Circuit design is the core of PCBA solution board design. Designers draw the schematic diagram based on the product’s functional requirements. The schematic defines the relationships between components, ensuring that the electrical performance meets specifications. This process involves considering factors such as voltage, current, and signal frequency.

- PCB Layout and Routing

After completing the schematic, the PCB layout phase begins. Designers need to arrange the component placement based on the circuit diagram and practical needs, and route the connections between components. This step must account for electromagnetic interference, signal integrity, and heat dissipation to ensure the circuit’s stability and reliability. - Component Selection and Procurement

Based on the circuit design, suitable electronic components must be selected. The choice of components not only considers functionality but also factors such as quality, cost, and availability. Proper component selection can reduce production costs while enhancing the stability and durability of the product. - PCBA Production and Assembly

After the design is completed, the production phase begins. The circuit board is manufactured by PCB manufacturers, followed by SMT (Surface Mount Technology) or THT (Through-Hole Technology) assembly, where components are placed on the board. Each assembly process must undergo strict quality control to ensure the final product’s quality. - Testing and Debugging

After assembling the PCBA solution board, it undergoes rigorous testing and debugging, including functionality testing, electrical performance testing, and temperature testing, to ensure that it meets the design requirements. During testing, adjustments and optimizations are made based on results, ensuring product stability and high performance.

Key Technologies and Challenges in PCBA Solution Board Design

- High-Density Integration Design

As electronic products become smaller and more complex, PCBA solution boards face the challenge of high-density integration. Designers must place more components in a limited space while ensuring stable signal transmission and good electrical performance. - Signal Integrity and Electromagnetic Compatibility (EMC)

In complex circuit designs, signal interference and electromagnetic issues often lead to reduced device performance. Therefore, designers need to employ advanced routing techniques such as high-speed signal routing and differential signal processing to ensure signal integrity and reduce electromagnetic interference through proper EMC design. - Thermal Management and Heat Dissipation

Heat management is a critical factor in PCBA solution board design, especially in high-power applications. Thermal design needs to account for heat distribution, material selection for heat dissipation, and the design of cooling channels to prevent overheating, which could degrade component performance or cause failure. - Automation in Production and Quality Control

With increasing production scale, PCBA solution board production has shifted towards automation. Automated production not only improves efficiency but also maintains quality while reducing costs. However, achieving automation requires advanced production equipment and process control, making quality control essential.

Applications of PCBA Solution Boards

- Consumer Electronics

PCBA solution boards are widely used in consumer electronics, such as smartphones, TVs, and computers, providing stable electrical performance and enabling various functions. - Communication Devices

In the telecommunications industry, PCBA solution boards are used in base stations, routers, switches, and other equipment to ensure efficient and stable signal transmission and data processing. - Automotive Electronics

PCBA solution boards are used in automotive control systems, sensors, navigation devices, and other critical components, enabling vehicles’ intelligent and electrified features. - Industrial Automation

In industrial automation, PCBA solution boards are employed in PLCs (Programmable Logic Controllers), sensor control, drives, and other key components to ensure efficient and precise production processes. - Medical Equipment

Many medical devices, such as monitoring systems, ultrasound machines, and diagnostic instruments, rely on PCBA solution boards to achieve precise functionality, ensuring high reliability and accuracy.

Conclusion

PCBA solution board design and development are core steps in electronic product manufacturing, involving circuit design, component selection, PCB routing, assembly, and testing. As electronic technology advances, PCBA solution board design faces numerous challenges, but through advanced design techniques and strict quality control, it is possible to ensure high performance and reliability. Whether in consumer electronics, communications, automotive, industrial automation, or medical devices, PCBA solution boards play a crucial role in driving technological innovation across industries.

Keywords: PCBA design, PCBA development, circuit design, PCB routing, component selection, electronic product manufacturing, SMT technology, THT technology