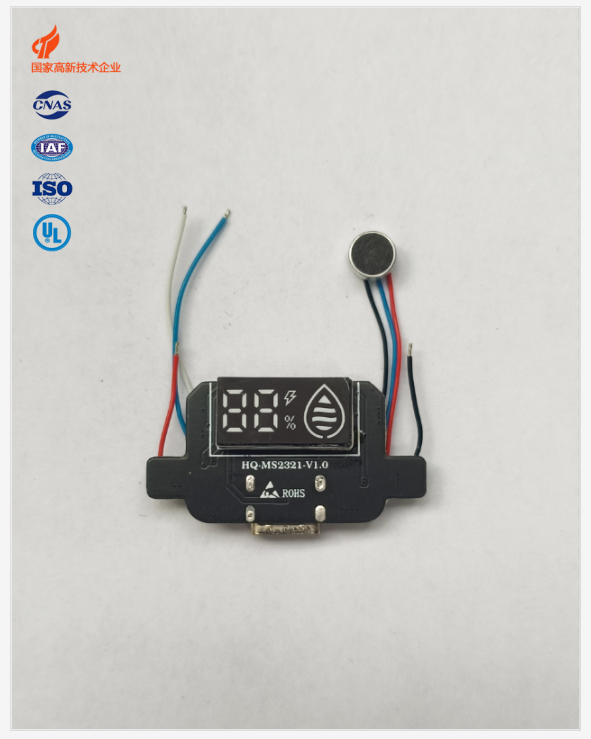

PCBA Control Board Electronic cigarette PCBA program board

PCBA program design services are ideal for small and medium-sized enterprises or individuals without a self-built design team. Our company translates the client’s design concept into concrete and viable technical solutions, from functional requirements discussion to hardware and software design and product manufacturing, providing a one-stop manufacturing solution. Novo Electronics has specialized in the design of PPA solutions for 10 years and has 2 design teams in design, development, DFM analysis, sampling and mass production. Both are college graduates with extensive PPA processing experience in various fields such as electronics, medical and home electronics. At the same time, according to different customer needs, to provide responsive flexible cooperation. In order to seize the consumer market, the electronic product design company needs a PCBA solution company with rich experience and technical support to transform the product concept into a physical product. We will be your first choice!

What is a CBD-PCBA Solution Board?

CBD-PCBA solution boards are designed specifically for CBD vaping devices, which are used for consuming CBD (cannabidiol) in the form of vapor. The PCBA in CBD vaping devices manages similar functions as electronic cigarette PCBA boards, but with additional features that optimize CBD extraction and vaporization. These boards control the temperature of the heating elements to ensure optimal vaporization of CBD oil, ensuring the device operates within a safe temperature range. Additionally, the PCBA in CBD devices often integrates special features like adjustable voltage, coil resistance monitoring, and safety cutoffs.

Key Steps in the Design and Development of Electronic Cigarette and CBD-PCBA Solution Boards

- Requirement Analysis and Function Definition

Before designing the PCBA, understanding the product’s requirements is crucial. For e-cigarettes and CBD devices, this involves defining features such as battery life, heating temperature, power output, and user interface design. Requirements such as compact design, durability, and safety regulations (e.g., protection against overheating and short circuits) must also be considered in the design phase. - Circuit Design and Schematic Drawing

In this stage, the designer develops the circuit schematics based on the requirements. The schematic diagram defines the electrical relationships between various components like the microcontroller, heating coil, battery, sensors, and display system. Special attention must be given to voltage regulation and temperature control to ensure optimal device performance. - PCB Layout and Component Placement

After finalizing the schematic, the next step is the PCB layout. The design focuses on the placement of components such as resistors, capacitors, transistors, and connectors. The layout should ensure that the circuit is efficient, compact, and minimizes interference or signal loss. Effective routing and placement of components also ensure that heat dissipation is well managed, especially in heating elements used in e-cigarettes and CBD vaporizers. - Component Selection and Procurement

Choosing high-quality components is critical to the performance and durability of the PCBA. For e-cigarettes and CBD devices, components like temperature sensors, microcontrollers, and power management ICs must meet stringent performance standards. The components also need to be reliable and durable to withstand the repeated heating and cooling cycles in the vaping process. - PCBA Assembly and Manufacturing

Once the PCB layout is finalized and components are selected, the next step is assembly. Depending on the design, this could involve Surface Mount Technology (SMT) or Through-Hole Technology (THT) for component placement. The assembly process requires precision to ensure proper soldering and connections, as any defects in the assembly could impact the device’s functionality. - Testing and Quality Assurance

After assembly, thorough testing is performed to ensure the PCBA functions as intended. This includes power testing, voltage checks, temperature monitoring, and overall device safety. Rigorous quality assurance ensures the device operates efficiently, safely, and without defects. Testing can also identify potential issues such as overheating or excessive battery drain, which are critical concerns for e-cigarette and CBD devices.

Challenges in E-Cigarette and CBD-PCBA Solution Board Design

- Heat Management

The heating elements in e-cigarettes and CBD devices generate significant heat during operation. Therefore, thermal management is crucial. The PCBA design must account for heat dissipation, using materials and components that can handle high temperatures without degradation. Additionally, efficient layout and proper ventilation help in maintaining safe operating temperatures. - Battery Life and Power Management

Efficient power management is essential in e-cigarettes and CBD vaporizers. The PCBA must ensure optimal battery usage while preventing overcharging, undercharging, or short-circuiting, which could damage the device or reduce its lifespan. Additionally, ensuring the device’s power output is consistent and stable is critical for user satisfaction. - Safety Features

Safety is a significant concern in e-cigarettes and CBD devices. The PCBA must include various safety features, such as overvoltage protection, temperature control, and short-circuit prevention. These features are crucial to prevent malfunctions or accidents that could harm the user. - Miniaturization

As consumer demand for smaller, more portable devices grows, miniaturizing the PCBA design without compromising functionality presents a challenge. Designers must ensure the PCB is compact while still accommodating all necessary components and maintaining a high level of performance.

Applications of Electronic Cigarette PCBA and CBD-PCBA Solution Boards

- Vaping Devices

The primary application for e-cigarette and CBD-PCBA solution boards is in vaping devices, where the PCBA controls the heating elements, monitors battery levels, and maintains temperature control for an optimal vaping experience. - Portable CBD Vaporizers

In the growing CBD market, portable vaporizers for CBD oil rely heavily on advanced PCBA designs. These devices require precise temperature control to ensure the effective vaporization of CBD without degrading the product. - Smart Vape Pens

Many modern vape pens incorporate smart technology, such as adjustable settings for temperature and voltage, which are controlled by the PCBA. These smart features allow users to customize their vaping experience. - Medical and Wellness Devices

E-cigarettes and CBD vaporizers are increasingly used in the medical and wellness industries for therapeutic purposes. PCBA designs in these devices ensure safety, efficiency, and reliability, making them suitable for medical applications like pain relief or anxiety reduction.

Conclusion

The design and development of electronic cigarette and CBD-PCBA solution boards are fundamental in ensuring the performance, safety, and reliability of vaping devices. As the demand for e-cigarettes and CBD vaporizers continues to grow, so does the need for innovative, efficient, and high-quality PCBA designs. By addressing challenges such as heat management, power efficiency, safety, and miniaturization, manufacturers can deliver products that meet the needs of modern consumers while maintaining high standards of safety and performance.

Keywords: Electronic Cigarette PCBA, CBD-PCBA, Vaping Device Design, Temperature Control, PCB Assembly, Power Management, Safety Features, Miniaturization